In complex technical and organizational environments, clarity depends on how systems are structured and identified. One concept that quietly supports order and efficiency is the subsystem number. Used across engineering, software, manufacturing, and infrastructure projects, this identifier helps break down complexity into manageable parts. Understanding how a subsystem number works and why it matters can significantly improve system management and communication.

What Is a Subsystem Number

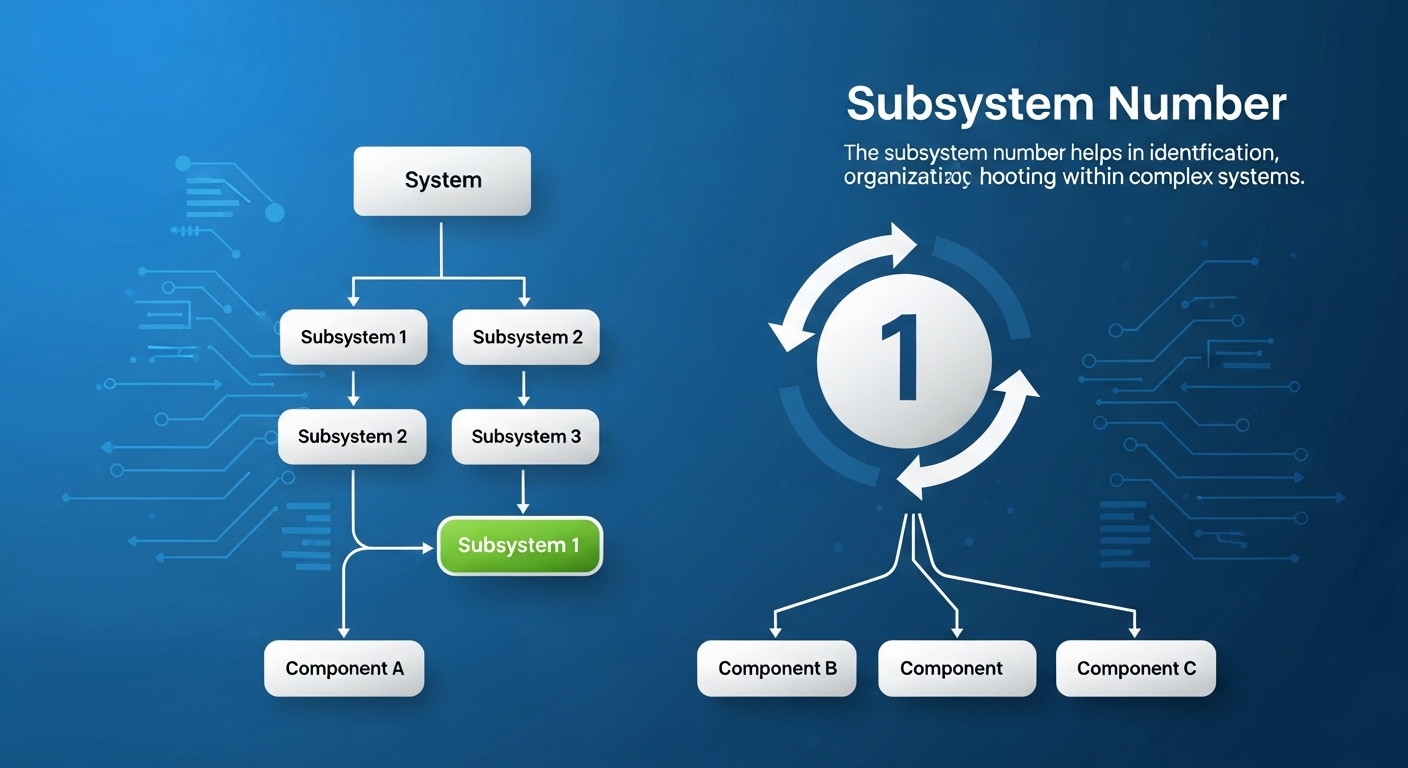

A subsystem number is a unique identifier assigned to a smaller functional unit within a larger system. It helps distinguish one subsystem from another while maintaining a clear relationship with the main system. By assigning a structured number, organizations can track components, responsibilities, and performance without confusion. This approach supports better documentation, easier troubleshooting, and more organized system design.

Why Subsystem Numbering Matters

The importance of a subsystem number lies in its ability to bring order to complex structures. When systems grow in size, managing components without a clear identification method becomes inefficient. Subsystem numbering enables teams to reference specific units quickly, reducing errors and miscommunication. It also improves collaboration between departments by providing a shared and consistent reference point.

Subsystem Number in Engineering and Manufacturing

In engineering and manufacturing environments, the subsystem number plays a key role in design, assembly, and maintenance processes. Each mechanical, electrical, or control unit can be tracked independently while still being part of a unified system. This makes it easier to update designs, replace components, and ensure quality control throughout the product lifecycle.

Use of Subsystem Number in Software Architecture

Software systems often rely on subsystem numbers to organize modules, services, and processes. By assigning identifiers to subsystems, developers can manage large codebases more efficiently. This structure supports version control, debugging, and scalability, allowing teams to improve or expand specific areas of the software without disrupting the entire system.

How Subsystem Numbering Improves Maintenance

Maintenance activities benefit greatly from a clear subsystem number structure. When an issue occurs, technicians can identify the affected subsystem quickly and respond with precision. This reduces downtime and lowers maintenance costs. Accurate subsystem identification also helps maintain historical records, making future inspections and upgrades more effective.

Best Practices for Managing Subsystem Numbers

Effective management of subsystem numbers requires consistency and clear documentation. Numbers should follow a logical sequence that reflects system hierarchy and function. When applied correctly, this practice ensures long-term usability and prevents confusion as systems evolve. A well-planned numbering approach supports growth, compliance, and operational efficiency.

Conclusion

The subsystem number is a fundamental yet often overlooked element of system organization. By providing clear identification and structure, it supports better design, communication, and maintenance across industries. Whether in engineering, software, or operations, using subsystem numbers correctly leads to more efficient systems and better long-term performance.