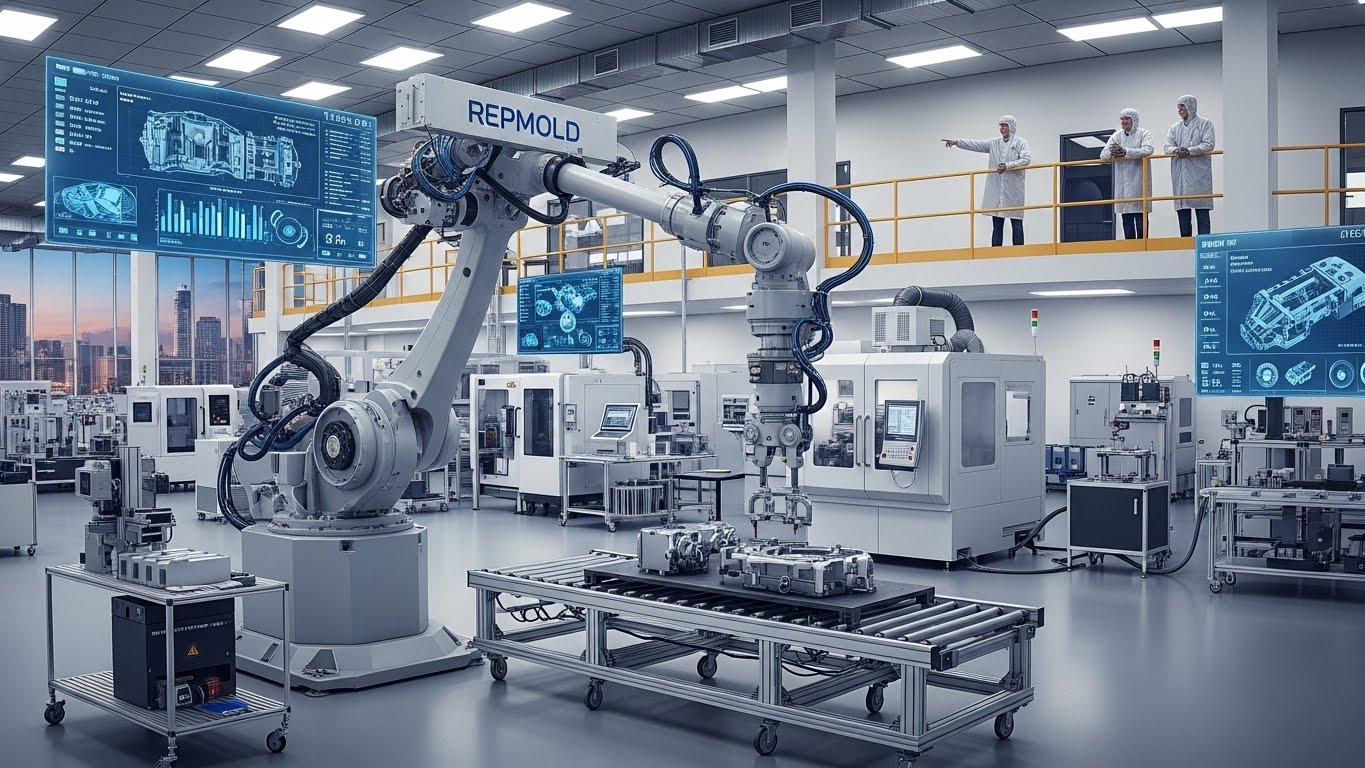

Repmold has become a widely discussed term in manufacturing and design circles, especially as industries look for efficient and precise replication methods. In today’s immaculate grid of production systems, where accuracy, repeatability, and cost control matter more than ever, repmold stands out as a practical solution. From prototyping to large-scale manufacturing, this process supports consistency while helping businesses meet tight deadlines and quality standards.

Unlike traditional molding techniques that often require starting from scratch, repmold focuses on recreating or refining existing molds. This approach fits perfectly into modern workflows where innovation builds on proven designs rather than replacing them entirely. As industries evolve, understanding how repmold works and why it matters is essential for engineers, designers, and decision-makers alike.

What Is Repmold and How Does It Work

Repmold refers to the process of reproducing an existing mold to create identical or slightly improved versions of a product. It is commonly used when the original mold is worn, damaged, or no longer available. By analyzing the existing part or mold, manufacturers can recreate it with high accuracy while maintaining the original design intent.

The repmold process usually begins with scanning or measuring the original component. Advanced tools such as 3D scanners and CAD software help capture every detail. Once the digital model is complete, it is used to produce a new mold that matches the original specifications. This method ensures continuity in production without unnecessary redesigns.

In the immaculate grid of modern manufacturing, where efficiency and precision intersect, repmold acts as a bridge between legacy designs and modern production techniques.

Why Repmold Matters in Today’s Manufacturing Landscape

The importance of repmold lies in its ability to save time, reduce costs, and preserve design accuracy. Many industries rely on legacy parts that are no longer supported by original manufacturers. Recreating these parts without a reliable reference can be expensive and risky. Repmold eliminates much of this uncertainty.

Another key advantage is scalability. Once a repmold is created, it can be used repeatedly to produce consistent parts. This consistency is vital in industries such as automotive, aerospace, and consumer goods, where even small deviations can lead to performance issues.

The table below highlights how repmold compares to traditional mold creation methods in practical manufacturing scenarios.

| Aspect | Traditional Mold Creation | Repmold Approach |

|---|---|---|

| Design Time | Longer due to full redesign | Shorter using existing reference |

| Cost Efficiency | Higher initial investment | Lower overall cost |

| Accuracy | Dependent on new design | High fidelity to original |

| Production Continuity | Possible delays | Minimal downtime |

Repmold in the Immaculate Grid of Product Development

In product development, the immaculate grid represents a balance of design, functionality, and manufacturability. Repmold fits neatly into this grid by allowing teams to iterate without losing alignment. When a product performs well in the market, there is often no need to reinvent it. Instead, repmold enables manufacturers to maintain the same design while upgrading materials or production techniques.

This is particularly valuable when companies expand into new markets or scale production. Rather than creating entirely new molds, repmold ensures that the original product identity remains intact. This consistency helps protect brand reputation and customer trust.

Applications of Repmold Across Different Industries

Repmold is not limited to one sector. Its flexibility allows it to be applied across a wide range of industries, each with its own unique requirements.

In the automotive industry, repmold is often used to reproduce interior and exterior components that are no longer in production. Aerospace manufacturers rely on repmold to recreate specialized parts with strict tolerance requirements. In consumer products, repmold helps brands maintain consistency across product lines while reducing tooling costs.

The following table outlines common industry applications and their specific benefits.

| Industry | Use of Repmold | Key Benefit |

|---|---|---|

| Automotive | Replacement parts and trims | Cost-effective replication |

| Aerospace | Precision components | High accuracy |

| Medical | Device housings | Regulatory consistency |

| Consumer Goods | Product scaling | Brand uniformity |

Benefits of Using Repmold for Long Term Production

One of the strongest advantages of repmod is long-term sustainability. By extending the life of existing designs, manufacturers reduce waste and minimize the need for constant redesign. This approach aligns well with modern sustainability goals.

Repmold also supports faster turnaround times. When production needs to resume quickly, having a repmod ready can prevent costly delays. This speed is crucial in competitive markets where time to market often determines success.

Additionally, repmod provides flexibility. Manufacturers can make small adjustments to improve durability or performance without altering the core design. This balance between stability and innovation is what makes repmod so valuable.

Challenges and Limitations of Repmold

While repmod offers many advantages, it is not without challenges. The accuracy of the final mold depends heavily on the condition of the original part. If the reference is damaged or distorted, recreating it accurately can be difficult.

Another limitation involves material compatibility. Older designs may use materials that are no longer available or compliant with current regulations. In such cases, repmod requires careful material selection to ensure performance remains consistent.

Despite these challenges, advances in scanning technology and digital modeling continue to improve the reliability of repmod processes.

How Repmold Supports Innovation Without Redesign

Innovation does not always mean starting from zero. In many cases, improving an existing product delivers more value than creating a new one. Repmod supports this philosophy by allowing manufacturers to focus on enhancements rather than reinvention.

By working within an existing framework, teams can test new materials, optimize production methods, or adjust dimensions while keeping the original design intact. This approach fits perfectly into the immaculate grid of continuous improvement, where progress is incremental but impactful.

The Future of Repmold in Advanced Manufacturing

As manufacturing technologies evolve, the role of repmod is expected to grow. Integration with artificial intelligence and machine learning will further enhance accuracy and efficiency. Automated analysis of original parts can reduce human error and speed up the replication process.

Additive manufacturing may also complement repmod by enabling rapid prototyping before final molds are produced. This hybrid approach combines the best of traditional molding and modern digital techniques.

In the future, repmod will likely become a standard practice rather than a specialized solution, especially in industries that value consistency and reliability.

Conclusion Repmold as a Key Element of the Immaculate Grid

Repmold plays a critical role in modern manufacturing by offering a practical, efficient, and reliable way to reproduce existing designs. Its ability to preserve accuracy while reducing costs makes it an essential part of the immaculate grid of production systems.

From automotive components to consumer goods, repmod supports continuity, innovation, and sustainability. As technology continues to advance, this process will remain a cornerstone of efficient manufacturing strategies. Understanding repmod today means being better prepared for the future of production.